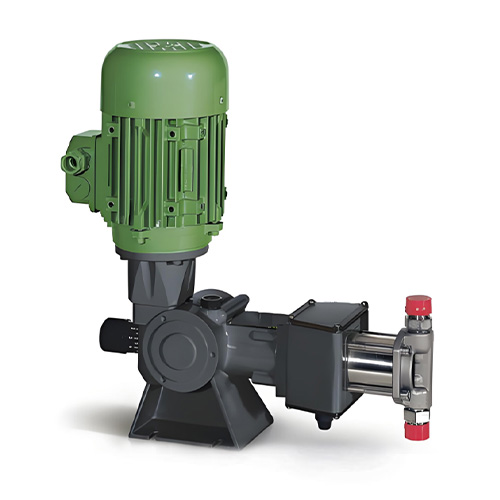

Looking to buy a plunger pump that delivers consistent pressure and long-term reliability? A plunger pump is a high-performance positive displacement pump designed for precision fluid transfer, ideal for industries requiring accurate dosing and sustained pressure. Whether you’re sourcing a chemical injection plunger pump or a high pressure plunger pump for sale, understanding how these pumps work can help you make a smarter investment.

What Is a Plunger Pump?

A plunger pump operates by moving a cylindrical plunger back and forth through a sealed chamber. This motion draws fluid in and then forces it out under pressure. Unlike diaphragm pumps, plunger pumps allow direct fluid contact with the plunger, making them highly effective in high-pressure systems.

Buyers searching for triplex plunger pump systems or industrial plunger dosing pumps often choose these models due to their superior pressure capabilities and robust design.

Key Advantages of Plunger Pump

- Handles Extreme Pressure: Plunger pumps can reach pressures over 1000 bar, perfect for water jet cleaning, hydraulic pressure systems, and more.

- Accurate and Stable Flow: Their design ensures steady, pulseless fluid delivery—ideal for metering and dosing applications.

- Durability Under Harsh Conditions: Many models use ceramic or stainless steel plungers to resist abrasion and corrosion.

- Low Operating Costs: Their high efficiency and long lifespan make them a cost-effective solution over time.

If you’re comparing plunger pump prices, it’s important to consider not just the upfront cost but also the lifecycle cost based on energy efficiency and maintenance intervals.

Common Application

- Oil & Gas: Widely used as chemical injection plunger pumps in pipeline operations.

- Industrial Cleaning: High-performance models are ideal for plunger pumps for water jet cleaning and pressure washing systems.

- Agriculture: Used for fertilizer injection pumps and high-precision spraying.

- Desalination: A key component in reverse osmosis high-pressure pump systems.

- Food & Beverage: For hygienic and accurate fluid transfer.

If you’re sourcing a plunger pump supplier for any of these applications, make sure they offer models tested for your industry-specific standards.

Choosing the Right Plunger Pump

Buyers often search for terms like best plunger pump for industrial use or where to buy plunger pumps near me. To make the right choice, consider:

- Required pressure and flow rate for your application.

- Fluid compatibility (corrosive, abrasive, etc.).

- Pump configuration—single-acting, double-acting, or triplex plunger pump.

- Availability of parts and service from your chosen plunger pump manufacturer.

Maintenance Tips for Long-Term Value

- Regular inspection of pump seals and packing glands

- Monitoring plunger wear and surface condition

- Timely lubrication and cleaning

- Using only genuine parts from your authorized plunger pump supplier

Following these practices helps maximize uptime and reduce operating costs—especially when working with high pressure plunger pump systems.

Conclusion

For industries demanding reliable, high-pressure fluid handling, investing in a plunger pump for sale with proven performance is a smart decision. Whether your needs are in chemical processing, cleaning, or agriculture, the right pump can increase efficiency and reduce downtime.

Explore high-quality, industrial-grade plunger pumps at BESQO Marine. As a trusted plunger pump supplier, we provide tailored solutions and competitive plunger pump prices—ready to ship for your next project.