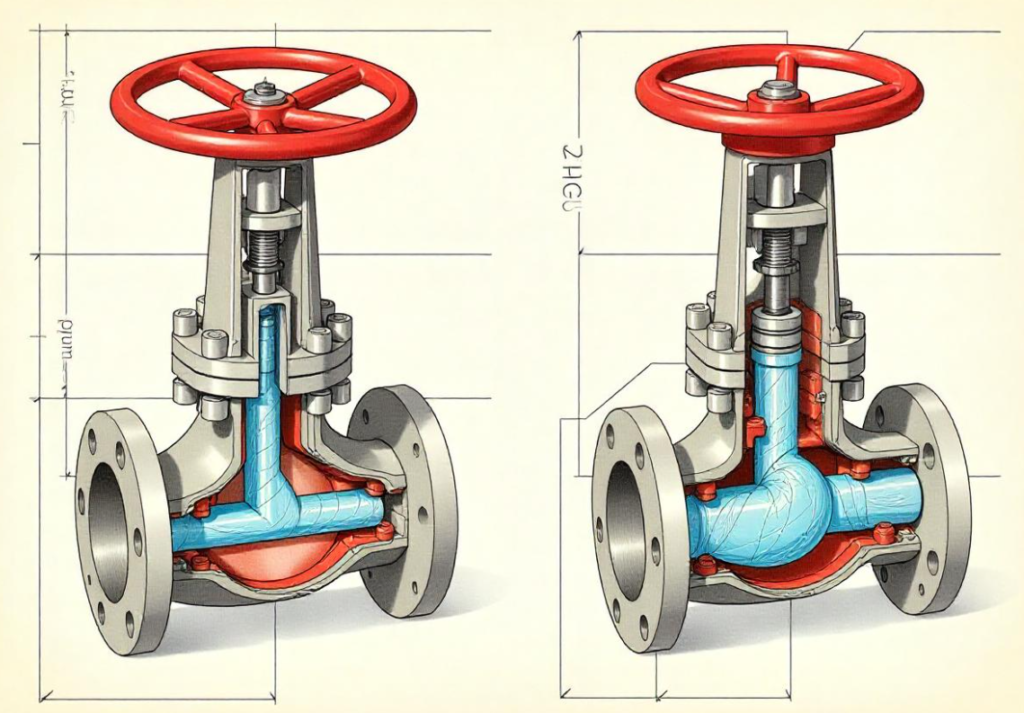

When it comes to selecting the right valve for your industrial, commercial, or residential needs, understanding the differences between a globe valve and a gate valve is crucial. Both valves serve distinct purposes and are designed for specific applications. This article will explore the key differences, advantages, disadvantages, and use cases of globe and gate valves, helping buyers make informed decisions.

What is a Globe Valve?

A globe valve is a linear motion valve used to regulate, start, or stop fluid flow. It consists of a movable disk (or plug) and a stationary ring seat in a spherical body. The disk is connected to a stem, which is operated manually or automatically to control flow.

Key Features of Globe Valves:

- Flow Regulation: Globe valves are excellent for throttling or regulating flow.

- Design: The spherical body design allows for efficient flow control.

- Pressure Drop: Globe valves create a higher pressure drop compared to gate valves due to their design.

- Sealing: They provide better sealing capabilities, making them ideal for applications requiring leak-tight closure.

Advantages of Globe Valves:

- Precise flow control and throttling.

- Good for frequent operation.

- Effective in high-pressure applications.

- Available in various materials for corrosion resistance.

Disadvantages of Globe Valves:

- Higher pressure drop can lead to energy loss.

- Heavier and bulkier compared to gate valves.

- More expensive due to complex design.

Applications of Globe Valves:

- Cooling water systems.

- Fuel oil systems.

- Chemical feed systems.

- High-pressure steam systems.

What is a Gate Valve?

A gate valve is a multi-turn valve designed to fully open or fully close the flow of fluid. It uses a flat or wedge-shaped gate that moves up and down to control flow. Gate valves are not designed for throttling but are ideal for on/off applications.

Key Features of Gate Valves:

- On/Off Control: Gate valves are primarily used for isolating fluid flow.

- Design: The gate moves perpendicular to the flow, creating minimal obstruction when fully open.

- Pressure Drop: Gate valves have a low pressure drop when fully open, making them energy-efficient.

- Sealing: They provide a tight seal when fully closed, but are not suitable for throttling.

Advantages of Gate Valves:

- Minimal pressure drop when fully open.

- Suitable for high-temperature and high-pressure applications.

- Simple design and easy to maintain.

- Cost-effective for large-diameter pipelines.

Disadvantages of Gate Valves:

- Not suitable for throttling or flow regulation.

- Slow to open and close.

- Prone to wear and tear if used for throttling.

Applications of Gate Valves:

- Water supply systems.

- Oil and gas pipelines.

- Fire protection systems.

- Slurry and viscous fluid handling.

Globe Valve vs. Gate Valve: Key Differences

| Function | Flow regulation and throttling. | On/Off control. |

| Design | Spherical body with a disk and seat. | Flat or wedge-shaped gate. |

| Pressure Drop | Higher pressure drop. | Lower pressure drop when fully open. |

| Sealing | Better sealing for leak-tight closure. | Tight seal when fully closed. |

| Operation | Suitable for frequent operation. | Slow operation, not for frequent use. |

| Cost | More expensive due to complex design. | Cost-effective for large pipelines. |

| Applications | Cooling systems, chemical feeds, etc. | Water supply, oil and gas pipelines. |

How to Choose Between Globe and Gate Valves

When selecting between a globe valve and a gate valve, consider the following factors:

- Purpose of Use:

- Choose a globe valve if you need precise flow control or throttling.

- Opt for a gate valve if you require a simple on/off mechanism.

- Pressure and Temperature:

- Globe valves are better suited for high-pressure and high-temperature applications.

- Gate valves are ideal for low-pressure drop systems.

- Frequency of Operation:

- Globe valves are designed for frequent operation.

- Gate valves are better for infrequent use.

- Cost and Maintenance:

- Globe valves are more expensive but offer better control.

- Gate valves are cost-effective and easier to maintain.

- Fluid Type:

- Globe valves are suitable for clean fluids and corrosive environments.

- Gate valves can handle slurries and viscous fluids.

Conclusion

Understanding the differences between globe and gate valves is essential for making an informed decision about the right valve for your needs. Whether you need precise flow regulation or reliable shutoff capabilities, each valve type offers unique advantages. By considering factors such as flow control, pressure drop, and maintenance requirements, you can ensure the best choice for your specific application.

At BESQO Marine, we offer a wide range of high-quality valves, including both globe and gate valves, to meet your operational needs. Visit our website for more information and expert guidance on choosing the right valve for your system.