When it comes to transferring thick liquids like oils, chemicals, and sludges, selecting the right pump can make a significant difference in operational efficiency. Double screw technology offers a unique solution for fluid transfer pumps that need to operate under demanding conditions. These pumps are designed to handle high-viscosity fluids with smooth, steady, and pulsation-free flow. In this article, we’ll explore the benefits, applications, and factors to consider when choosing a screw pump for your business.

What is a Double Screw Pump?

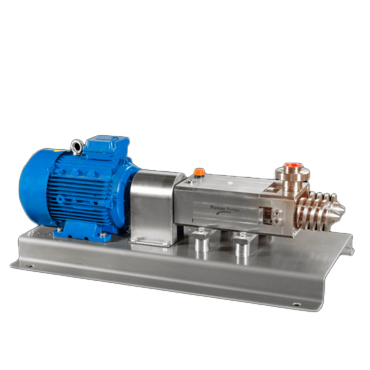

A twin screw pump, commonly referred to as a double screw pump, consists of two intermeshing screws that rotate within a casing. As the screws turn, they create cavities that transport the fluid, ensuring a continuous and stable flow. This makes them ideal for pumping thick liquids that other pumps struggle to handle. The positive displacement mechanism ensures that even highly viscous fluids are moved efficiently without causing turbulence or vibration.

Key Features of Twin Screw Pumps

When deciding on the ideal pump for high-viscosity fluids, twin screw pumps provide several distinct advantages that can improve both the efficiency and cost-effectiveness of your operations.

- Smooth Flow: These pumps provide a constant, pulsation-free flow, perfect for sensitive applications where maintaining a steady output is crucial.

- High Viscosity Capability: Ideal for thick liquids like oils, paints, adhesives, and other viscous fluids, making them suitable for industries like oil & gas, food processing, and chemical manufacturing.

- Durability: Constructed with corrosion-resistant materials such as stainless steel, twin screw pumps are built to last, offering long-term reliability in harsh conditions.

- Self-Priming: These pumps typically do not require an external priming system, making them easier to install and maintain.

Common Applications of Twin Screw Pumps

These pumps are highly versatile and used in several industries, thanks to their efficient fluid transfer capabilities. Some of the key applications include:

- Oil & Gas: Crude oil transport, lubrication systems, and hydraulic oil transfer.

- Food & Beverage: Ideal for pumping syrups, sauces, and dairy products without compromising quality.

- Chemical Processing: Suitable for handling chemicals, paints, and adhesives that require careful and consistent pumping.

- Wastewater Treatment: Used in sewage treatment and for handling sludge with ease.

Why Choose a Twin Screw Pump for Fluid Transfer?

Selecting the right pump can be challenging, but double screw pumps offer a distinct advantage in several key areas:

- Energy Efficiency: These pumps are designed to handle high-viscosity fluids without excessive energy consumption. Their smooth and efficient design reduces the need for high power, leading to lower operating costs.

- Reduced Wear & Tear: The gentle, non-turbulent nature of the flow means less wear on internal components, resulting in longer operational life and reduced maintenance needs.

- Quiet Operation: Unlike some traditional pumps, twin screw pumps operate with minimal noise and vibration, making them ideal for settings where quiet performance is important.

- Ease of Maintenance: Thanks to their simple design and fewer moving parts, screw pumps are easy to maintain. Regular servicing is straightforward, and parts are readily available, reducing downtime and maintenance costs.

How to Choose the Right Twin Screw Pump for Your Needs

When deciding on the best positive displacement pump for your operation, consider the following factors to ensure optimal performance:

- Flow Rate & Pressure Requirements: Match the pump’s flow rate with your specific needs. Pumps are available in various sizes to handle different flow and pressure ranges.

- Viscosity of the Fluid: Ensure that the pump can efficiently handle the type of fluid you are transferring. Heavy oil pumps, for example, require different specifications than those used for lighter liquids.

- Material Resistance: Choose a pump that is compatible with the fluids you are pumping. Pumps designed for chemical transfer may need additional features like corrosion resistance or abrasion protection.

- Pump Configuration: Consider whether you need a self-priming pump or one that is more suited for continuous operation in a closed system.

Conclusion

Whether you’re working in oil & gas, chemical manufacturing, or food processing, choosing the right positive displacement pump is crucial to maintaining efficiency and cost-effectiveness. Twin screw pumps stand out for their ability to handle high-viscosity liquids with minimal operational costs and maintenance needs, making them an ideal solution for demanding fluid transfer applications.

For more information about high-quality twin screw pumps and other reliable fluid transfer solutions, contact BESQO Marine. We offer a wide range of products tailored to meet your specific needs, ensuring efficiency and reliability in every application.