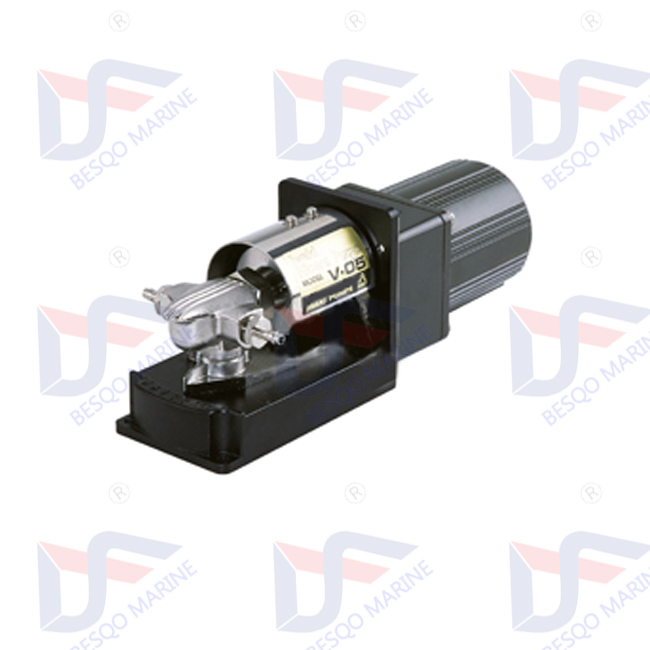

Metering Pump –V Series Introduction

Specification Table

| Discharge capacity | 0.30/0.4 to 1400/1682 mL/min |

| Max. discharge pressure | 0.7 MPa |

| Main materials | Alumina ceramic, SiC, SUS316 |

| Required power range | 6 to 40 W |

| Liquid temp. range | 0 to 120 C deg. |

| Viscous liquid | 20000 mPa•s (depending on model) |

| Slurry liquid | Please contact us for details. |

| Seal method | Lip seal |

Specification Table Product Description

Preventing clogging and sticking with valveless construction

High discharge accuracy

The main components such as the plunger and cylinder are processed with high precision of micron order, so it is possible to obtain high discharge accuracy. (Discharge accuracy: ±0.5%) By changing the angle of the pump head it is possible to freely adjust the discharge amount between 0 and maximum discharge.

Excellent corrosion resistance

Materials such as silicon carbide (SiC), fluorocarbon polymers (PTFE) and stainless casting (SCS14) with excellent resistance to corrosion are used for parts that come in contact with the fluid. This makes it possible to use the pumps for handling a wide range of chemicals.

Dispense into a vacuum condition and removal from a high-pressure condition

Since there are no suction and discharge valves, it is possible to directly dispense a constant amount of fluid in a vacuum (negative pressure) without using a solenoid. Constant-volume dispensing is also possible if suction side is pressurized.

Capable of handling slurries and highly viscous fluids

The unique valveless construction and the excellent resistance to wear of SiC, it is possible to handle slurries with fast precipitation speed as well as abrasive slurries. Also, the pumps are capable of smoothly pumping highly viscous fluids up to a maximum viscosity of 20,000 mPa・s.

Note: The discharge accuracy drops for viscous fluids with a viscosity of 500 mPa・s or greater. Contact this company for details.

The V Series Metering Pump delivers precise fluid dispensing with ±0.5% accuracy. Its valveless design prevents clogging, allowing it to handle slurries and viscous fluids up to 20,000 mPa·s. With a discharge capacity from 0.30 to 1682 mL/min and a max pressure of 0.7 MPa, it’s built with corrosion-resistant materials for reliability in chemical applications. It operates efficiently in both vacuum and high-pressure conditions.